Since 1896, the National Fire Protection Association (NFPA) has been at the forefront of providing crucial fire prevention and safety standards for buildings and businesses across the United States. One of its vital documents, the NFPA 70E, Standard for Electrical Safety in the Workplace, has been a cornerstone for organizations with energized assets since 1979.

This comprehensive standard has enabled facilities to establish robust safety protocols, make informed decisions regarding personal protective equipment (PPE), and accurately assess arc flash risks.

In keeping with its commitment to staying abreast of evolving technology and research, the NFPA updates the NFPA 70E every three years. 2024 marks the 13th iteration and introduces several significant changes aimed at enhancing employee safety. Sign your employees up for our online NFPA 70E Open Enrollment classes!

Notable Term Changes for NFPA 70E 2024 Update

In the 2024 update of NFPA 70E, significant revisions have been made to the “Term Changes” section, ensuring precise and consistent language for better understanding and application. These updates eliminate ambiguity and provide clear definitions, particularly when addressing “electric shock” and “shock wave” in various contexts.

By refining these terms and clarifying their usage, the NFPA aims to bolster workplace safety and empower organizations to make well-informed decisions regarding PPE and safety protocols.

Electric Shock

In an earnest effort to promote uniformity in usage, the NFPA 70E 2024 update has strategically placed the term “electric shock” ahead of “shock.” This precise arrangement ensures consistent interpretation throughout the standard. However, it is imperative to note that in references to “hearing protection boundary” and “lung protection boundary,” the term “shock” pertains specifically to the phenomenon of a “shock wave” and not to the more common “electric shock.”

Protectors

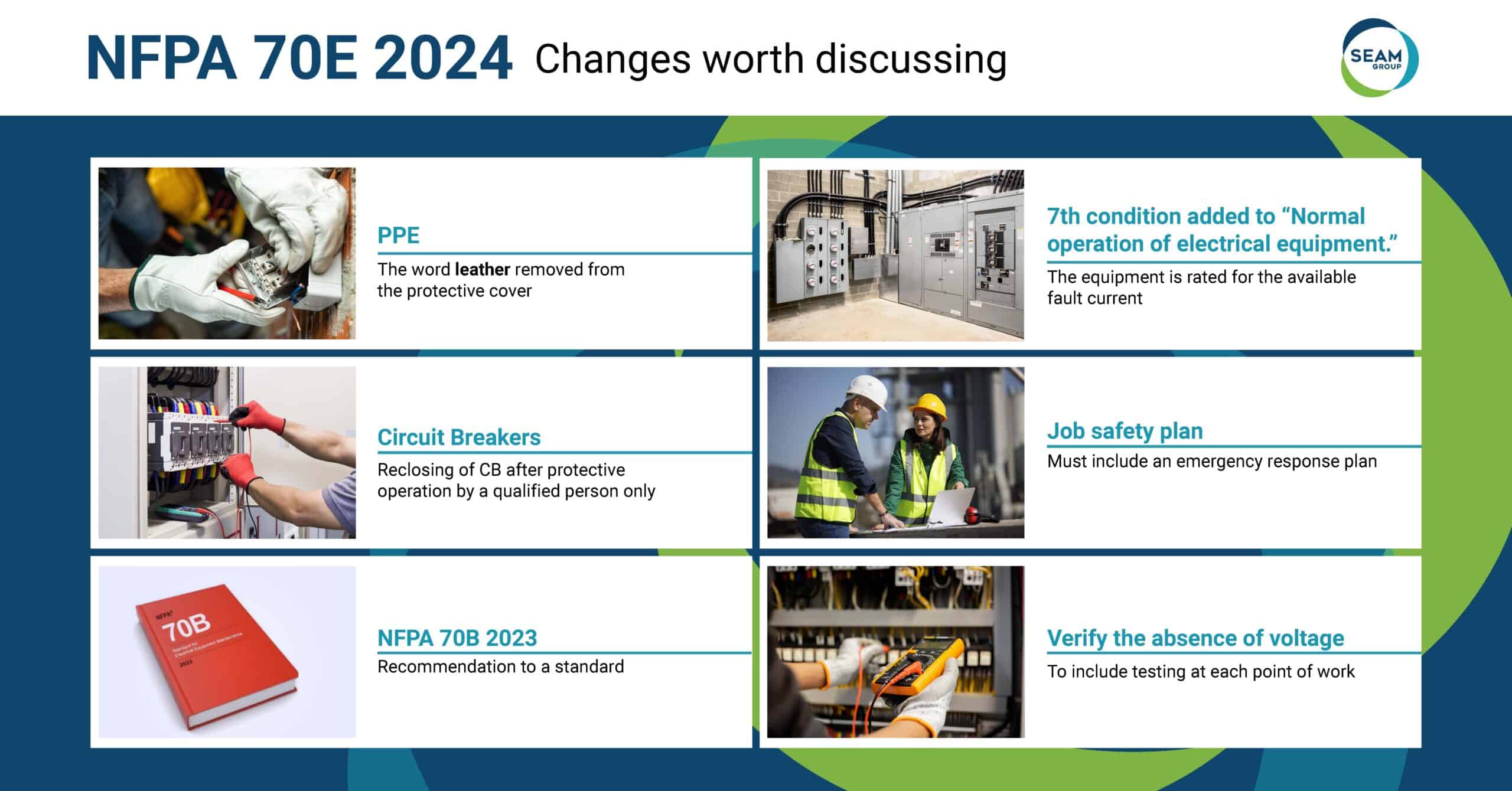

To embrace technological advancements and encourage versatility, the 2024 edition has thoughtfully removed the term “leather” from the equation. This prudent revision allows organizations to utilize protectors crafted from alternative materials, providing diverse options that better align with modern safety requirements and preferences.

Scope

Recognizing the importance of a comprehensive understanding, each article within the updated NFPA 70E now begins with a meticulously crafted scope. These overviews grant readers a clear vision of the content they will explore, facilitating more efficient navigation and informed decision-making regarding electrical safety protocols and measures.

Article 100 Definitions: A Comprehensive Lexicon for Enhanced Accessibility and Clarity

To improve user experience and accessibility, the 2024 update of NFPA 70E has compiled all definitions into the revamped Article 100. This consolidation streamlines the standard, providing users with a centralized library of essential terms and concepts. Moreover, the update has revamped the title structure, ensuring seamless electronic searching capabilities and quicker access to critical information.

The NFPA has also incorporated critical updates to include definitions for protectors, ionizing radiation, and non-ionizing radiation. By defining these terms, the standard empowers facilities and organizations with the knowledge necessary to make informed decisions when crafting safety protocols and selecting appropriate PPE.

With Article 100 now serving as the cornerstone of definitions within NFPA 70E, users can navigate the intricacies of the standard, fostering safer work environments and equipping personnel with the tools needed to mitigate electrical hazards.

Article 110: General Requirements for Electrical Safety-Related Work Practices

In the latest edition of NFPA 70E, many changes have been made to the standard governing Electrical Safety-Related Work Practices Article 110.

Article 110.2(B) – When required.

One noteworthy change in this section is the alteration of the phrase “Normal operation of electric equipment” to “Normal Operating Condition.” This update expands the permissible scenarios for the normal operation of electric equipment. Newly Added Normal Operating Condition: “Normal operation of electric equipment shall be permitted where a normal operating condition exists.”

A normal operating condition is deemed to exist only when the following conditions are met:

-

- The equipment has been properly installed.

- The equipment is well-maintained.

- The equipment is rated to handle the available fault current.

- The equipment is utilized strictly per the manufacturer’s instructions, as stated in the listing and labeling.

- The equipment doors are securely closed.

- All equipment covers are firmly in place and secured.

- There are no apparent signs of impending failure. (New note: This specifically includes protection against water damage).

Note: The available fault current information should be readily accessible, listed on the electrical equipment’s manufacturer’s information label, and on circuit breakers.

These updates to Article 110 ensure a more comprehensive understanding of when normal operating conditions apply. Following these guidelines will enhance electrical safety practices and minimize potential risks in electrical work environments.

By adhering to the latest NFPA 70E standards, your people can better protect themselves and others from electrical hazards.

Identification of Impending Failure: New Addition

Another crucial update in Article 110.2(B) is the inclusion of “Another example of evidence of impending failure.” This highlights the significance of identifying water-damaged electrical equipment as an indicator of potential hazards. It emphasizes the need for regular inspections to ensure the safety of electrical equipment and personnel.

Ref: NEMA GD 1-2019

These updates to Article 110 help provide a more comprehensive understanding of normal operating conditions and the identification of impending failure. By following these guidelines, your professionals can enhance electrical safety practices and minimize potential risks in electrical work environments.

Article 110.3 Job Safety Planning: Strengthening Electrical Safety

One of the key enhancements in the latest edition of NFPA 70E pertains to Article 110.3 – Job Safety Planning. This section now includes a vital addition, “6. An emergency response plan,” to the list of required information for comprehensive job safety planning. Let’s explore these updates in detail to grasp their importance.

To ensure effective job safety planning, the new NFPA 70E edition mandates the following guidelines:

(1) Completion by a Qualified Person

The job safety plan must be developed and reviewed by a qualified individual with expertise in electrical safety. This ensures the plan is reliable and tailored to address specific electrical hazards.

(2) Documentation

Thorough documentation is essential to create a comprehensive job safety plan. Proper records ensure easy accessibility and enable continuous improvement in safety practices.

(3) Inclusion of the following information:

-

- Description of the Job and Individual Tasks: A detailed description of the job and the specific tasks involved provides a clear understanding of the work requirements.

- Identification of Electrical Hazards: For each task, comprehensive identification of associated electrical hazards is crucial for implementing appropriate safety measures.

- Electric Shock Risk Assessment: Tasks involving electric shock hazards must undergo a risk assessment following the guidelines outlined in 130.4. This assessment ensures that personnel are well-prepared to mitigate electrical shock risks.

- Arc Flash Risk Assessment: A risk assessment in accordance with 130.5 is mandatory for tasks involving arc flash hazards. This assessment helps prevent potential arc flash incidents and minimizes their impact on personnel and equipment.

- Work Procedures, Special Precautions, and Energy Source Controls: Thorough documentation of the necessary work procedures, special precautions, and energy source controls is vital to maintain a safe work environment.Emergency Response Plan: The newly added requirement, an emergency response plan, is a crucial component of job safety planning. This plan must address the specific steps to be taken during an electrical shock or an arc flash incident. Preparing for emergencies is just as crucial as preventing them.

Note: Addressing Electrical Shock and Arc Flash Incidents

It is essential that your emergency response plan clearly outlines the appropriate actions to be taken in case of an electrical shock or an arc flash. This ensures that personnel can respond promptly and effectively to such incidents.

By adhering to these updated guidelines in Article 110.3, your organization can strengthen its job safety planning and enhance electrical safety practices. Emphasizing the importance of an emergency response plan ensures that your facilities are well-prepared to handle unforeseen events, safeguarding both personnel and equipment from potential hazards.

Article 120: Establishing an Electrically Safe Work Condition

In the latest edition of NFPA 70E, specific changes have been introduced to Article 120, focusing on “Establishing an Electrically Safe Work Condition.” A new informational note, Article 120.5 (A)(1), has been added, shedding light on the importance of locating sources of supply during this process.

Article 120.5 (A)(1) Locating Sources: New Informational Note

An informative addition to Article 120.5 (A)(1) emphasizes the significance of locating supply sources while establishing an electrically safe working condition. This step is critical in ensuring comprehensive electrical safety measures.

New Informational Note:

“Locating sources of supply could include identifying situations where a neutral conductor continues to carry current after phase conductors have been de-energized.”

Note: Illustrative Example

To better understand the importance of this note, let us consider an illustrative example. Imagine the removal of a light ballast from a 277-volt 3-phase multi-wire branch circuit. In such cases, the neutral conductor may continue to carry current even after the phase conductors have been de-energized. Identifying and addressing such situations is vital to creating electrically safe work conditions.

By acknowledging this updated informational note, professionals can implement more effective safety practices during the establishment of electrically safe work conditions. Thoroughly locating sources of supply ensures that all potential hazards are adequately addressed, mitigating risks for workers, and promoting a safer work environment.

Adhering to the latest NFPA 70E standards and embracing these updates will undoubtedly strengthen electrical safety measures, protecting workers and facilities from potential electrical accidents during maintenance and repair operations.

Article 120.6 Process for Establishing and Verifying an Electrically Safe Work Condition: New Step Added

The latest edition of NFPA 70E brings significant updates to several sections, focusing on “Establishing and Verifying an Electrically Safe Work Condition,” Arc Flash Risk Assessment, PPE guidelines, and Circuit Reclosing.

An additional step has been incorporated into the process of “Establishing and Verifying an Electrically Safe Work Condition.” This new step requires testing each phase conductor or circuit part at each point of work for the absence of voltage. A practical example of this process could be testing a three-phase motor feed from an electrical panel to ensure safety during maintenance.

Article 130.5 Arc Flash Risk Assessment: Informational Note Added

Within Article 130.5, a new Informational Note emphasizes the importance of wearing PPE when operating electrical equipment with secured covers and doors. For instance, disconnect switches may require additional protection, as closed doors might not always provide sufficient safety, especially in situations where the state of the equipment can change rapidly (e.g., doors open or closed, rack-in or rack-out).

Article 130.5(G) Incident Energy Analysis Method: Informational Notes Included

Informational notes have been added to Article 130.5(G) to provide examples of changes that could impact an “incident energy analysis.”

Examples:

- Changes in available fault current from the electric utility company

- Transformer size changes

- Modifications to protective devices or protective device settings

- Improper or inadequate maintenance of circuit breakers.

Article 130.7(C) Personal Protective Equipment (1) General: Improved Safety Measures

In cases where a “Danger Label” indicates that incident energy exceeds 40 cal/cm² on electrical equipment, personnel must take specific precautions to verify the absence of voltage. Adding an Information Note suggests installing a non-contact capacitive test instrument or a permanently installed metering device inside the equipment to reduce the likelihood of an arc flash event.

However, it emphasizes that an arc flash suit rated for the incident energy exposure level must still be worn while physically testing for voltage absence.

Note: The term “Proximity test instrument” removed, and 1000-volt limitation removed.

Table 130.7(C)(15)(b) Arc Flash PPE Categories for DC Systems: Voltage Parameter Adjustments

The voltage parameters in this table have been modified to “Greater than 150 volts and less than or equal to 600 volts” for DC systems. The revision is based on recent arc flash data, indicating that potential arc flash incidents may not be sustainable below 250 volts.

Article 130.8(M) Reclosing Circuits After Protective Operation: Clarification on Manual Reset

The wording of Article 130.8(M) has been updated to clarify that only a “Qualified Person” can manually reset circuit breakers after they have operated (tripped). Also, manually reclosing circuit breakers or re-energizing circuits through replaced fuses is prohibited until the fault’s cause is determined and cleared.

By incorporating these updates and adhering to the latest NFPA 70E standards, your workers can significantly enhance electrical safety protocols, minimize potential risks, and create safer work environments.

Informative Annex S—Assessing the Condition of Maintenance

A valuable addition to the NFPA 70E standard is the newly included Informative Annex S, which aims to assess the condition of electrical equipment maintenance. This annex refers to the 2024 edition of NFPA 70B, which serves as a reliable standard for electrical equipment maintenance, offering further insights into the assessment process. NFPA 70B establishes guidelines to achieve and maintain an acceptable condition of maintenance for electrical equipment and systems, focusing on safety and reliability.

Annex S refers to the NFPA 70B Standard, specifically in section S.8. NFPA 70B, titled “Recommended Practice for Electrical Equipment Maintenance,” complements NFPA 70E by providing additional, comprehensive information and guidelines for assessing the condition of maintenance of electrical equipment.

NFPA 70B: Enhancing Safety and Reliability

NFPA 70B is a recognized standard that plays a vital role in ensuring the safety and reliability of electrical equipment and systems. It establishes effective methods and practices to help your team achieve and sustain an acceptable level of maintenance, addressing safety concerns and promoting reliable operation.

By incorporating Informative Annex S and referencing the NFPA 70B Standard, your workers can gain valuable insights into assessing maintenance conditions, making informed decisions, and implementing appropriate measures to maintain electrical equipment in optimal working condition.

This proactive approach helps prevent potential hazards, safeguard personnel, and ensures the uninterrupted operation of electrical systems.

Meeting the NFPA 70E Standards: Ensuring Safety with SEAM Group’s Expertise

Implementing and adhering to NFPA 70E standards is paramount in establishing a safe workplace. The 2024 NFPA 70E updates require careful consideration and proper implementation to ensure electrical safety.

If your facility needs assistance addressing the changes introduced by the 2024 NFPA 70E, SEAM Group is here to help. As a global leader in optimizing energized assets’ safety, performance, and maintenance, we possess the expertise to guide and support your organization.

With SEAM Group’s assistance, you can confidently navigate the complexities of NFPA 70E and meet the latest safety standards. Our expert global team is ready to ensure that your workplace remains compliant while protecting your employees from electrical safety issues. Reach out to SEAM Group today for tailored solutions and comprehensive support.