ViewPoint, Scalable Technology to Enhance Safety, Reliability, and Maintenance

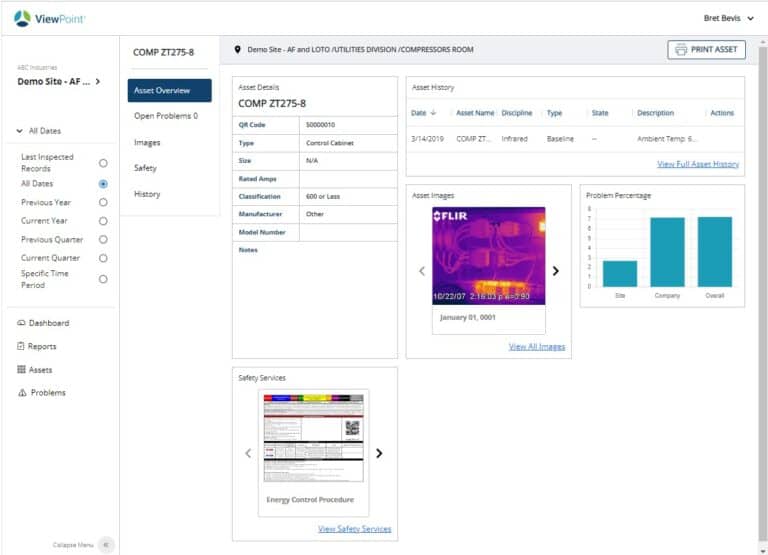

Serving as a single pane of glass, ViewPoint gives you a clear line of sight into critical safety and reliability insights for all your energized assets. This multi-disciplined platform digitizes condition-based maintenance and safety data across multiple facilities and assets to enable better decision-making.

The platform combines and analyzes data gathered from infrared, vibration, oil, ultrasound, motor current testing, and safety services like arc flash hazards analysis and digital lockout/tagout programs. ViewPoint supports data management for one or hundreds of facilities and enables personalized levels of access for multiple users. Even better, users can access ViewPoint through our web portal or ViewPoint On-Demand app.

Who Uses ViewPoint?

SEAM Group serves customers across multiple sectors, including distribution, logistics, hospitality, manufacturing, electric vehicle charging, data centers, food production, healthcare services, building management, and more.

Since its implementation, ViewPoint has been utilized by more than 7,000 registered users and reported more than $200 million in energy savings!

ViewPoint Unlocks Insights and Value

As a SEAM Group customer, you can make informed decisions and enjoy the many benefits of ViewPoint, some of which include:

- Reducing risk by providing asset safety data at the point of work, including PPE, incident energy, and LOTO procedures via QR code

- Maximizing uptime by identifying and prioritizing repairs based on criticality

- Initiating corrective actions early to reduce energy spend and lessen the impact to operations schedule

- Accessing current and historical condition monitoring data, including repairs and costs

- Single source management for condition monitoring services, including visual inspection images

- Quantifying and collating energy savings from the proactive repair of electrical thermal issues by location, asset, or any customized view

- Budgeting and scheduling annual inspections to ensure OSHA and NFPA compliance

Additionally, you get value through:

- Reduction of data entry mistakes by seamlessly integrating ViewPoint to your CMMS or data visualization platform via API

- Side-by-side comparisons of asset history

- Data management including tracking, sorting, reporting, and exporting

- Ability to digitally manage and execute your Lockout/Tagout program and deployment, eliminating reliance on paper methods to increase safety compliance

Reducing Risk and Increasing Energy Savings Since 2005

A ViewPoint Case Study

A leading food processor was encouraged by its insurance provider to implement an infrared inspection (IR) plan across its portfolio of 200+ facilities in North America.

SEAM Group integrated ViewPoint into the ongoing project to best gather, optimize, and share the customer’s most critical data across multiple locations.

Here are some of the highlights captured by ViewPoint:

- $1.5 million+ energy savings per year tracked through ViewPoint

- 30,000+ electrical panels inspected annually

- 5,000+ issues identified annually

- 98% issue closeout rate