Comprehensive Lockout Tagout Solutions

- Lockout Tagout Solutions

Lockout Tagout Key Components

Key Components of an Effective Lockout Tagout Program

The potential risk of unexpected energization is real when people work around energized assets. Whether the energy source is electrical, chemical, pneumatic, hydraulic, or mechanical, overlooking critical steps in de-energizing, releasing stored energy, or reenergizing assets during service and maintenance activities can lead to severe consequences. A comprehensive lockout tagout (LOTO) program is a safety linchpin for your organization which can help you.

- Protect your people from the dangers of the accidental energization of equipment during servicing and maintenance activities.

- Comply with federal, state, local, and internal requirements and policies.

- Meet your insurance requirements for premium benefits.

- Enhance the life, operability, and maintainability of your energized equipment.

- Reduce waste, rework, and unplanned downtime.

The key components of a comprehensive LOTO program:

A documented LOTO program

Employers need to establish a documented energy control program that covers the control of hazardous energy through risk assessments, procedures, training, inspections, roles and responsibilities, and equipment.

Written energy control procedures

Energy control policy and procedures Updates when equipment changes/updates take place Alternative protective measures

Periodic inspections

Annual inspections by a qualified person as required by NFPA 70E Article 120 and OSHA 1910.147 Audit needs to cover at least one LOTO in progress

Employee training

Required training for authorized and affected people Required every three years at a minimum or when equipment or processes change Retraining any time there is a change in procedure or an employee has been witnessed not complying with the LOTO procedure

Just how much is the cost of a workplace injury?

The cost and effects of a workplace injury go beyond claims and fines. A serious OSHA violation penalty can be up to $15,6251 The penalty for a willful or repeated violation can be up to 10x higher! $156,2592 The average cost of a workplace injury claim is $41,3533

It is conservatively estimated that for every dollar spent on workers’ compensation, you can spend $2.12 on indirect costs3 including legal fees, administrative time, recovery of lost production, quality, morale, etc.

$41,353 + ($41,353 x $2.12) = $129,021

So, the actual average cost of a workplace injury can be $129,000! Remember, this varies by industry.

If your company operates at a 10% profit margin, you will need an additional $1,290,000 in revenue to pay for the injury.

Meeting You Where You Are

SEAM Group joins your lockout tagout program development and implementation journey to serve as a safety advisor and boots-on-the-ground partner. We can be part of your entire journey or support you wherever you need us.

Lockout Tagout Gap Assessment

Risk-based LOTO gap assessment

Our LOTO gap assessment follows best practices and requirements defined by OSHA 1910.147, EU Directive & Guidelines 89/655, federal, state, local, and internal requirements and policies. During the site visit, our experts review your current LOTO Program and procedures with your team to develop a report with key findings and recommendations.

Upon completing our site visit, we will identify the maturity and gaps of your LOTO program, with a link to corporate governance and related safety processes. You will receive our findings and recommendations in a comprehensive report outlining gaps and corrective actions in lock out and tag out procedures, equipment documentation, and employee training needs. Our final deliverable is customized to meet your preferences and can include a workshop to develop an action and implementation plan.

The LOTO gap assessment covers vital elements that will inform your LOTO policy and procedure development.

- Your current LOTO program and documentation

- The accuracy, availability, accessibility, documentation, and annual review of your LOTO procedures

- The use of your LOTO procedures in work preparation and execution

- Enhance the life, operability, and maintainability of your energized equipment.

- Your LOTO program communication and safety culture

- Your LOTO training system, availability, compliance, and tracking

- LOTO in your capital project management framework

Lockout Tagout Program

Program and policy development

Our Process

Whether you need to develop a brand new LOTO program or revamp your existing one, our team of experts will help. The process begins with acquiring and reviewing your asset list, policies, and documents. We will then perform a site verification and develop a written program to meet your internal requirements plus the ANSI Z244.1, OSHA 1910.147, and EU Directive & Guidelines 89/655 as applicable.

Your new or updated LOTO program and policy will contain key elements:

- Purpose and scope

- Definitions of key terms

- Roles and responsibilities of authorized and affected employees

- Training and retraining content and policy

- Detailed LOTO procedures

- Communication practices and mechanisms

- LOTO devices selection and use guidelines

- Periodic loto inspections

- Special conditions

- Emergency procedures

- Enforcement and disciplinary actions

- Documentation and record keeping

- Outside contractors

- Return to service

Lockout Tagout Procedures

Procedures development

Our ViewPoint® technology powers our comprehensive approach to procedure development and implementation.

The LOTO gap assessment covers vital elements that will inform your LOTO policy and procedure development.

- Acquire and review your asset list

- Field verification of assets and identification of energy isolation points (EIP) for each asset.

- Identify energy control points

- Identify energy sources

- Take into consideration any machine guarding requirements related to the LOTO procedure

- Upload field data in ViewPoint and develop the procedures

- Produce the final customized electronic procedure in PDF format if necessary*

- Apply labels with unique QR codes to each energy isolation point to provide access to relevant procedures at the point of work and prevent errors during servicing and maintenance.

- Quality check by a senior safety expert to ensure information and procedures match field verification and QR codes work correctly.

*If you signed up for ViewPoint Digital Lockout Tagout access, your interactive procedures will be available through our ViewPoint mobile application for use at the point of work, and through our ViewPoint web portal for management.

Lockout Tagout Training

Training

Our Training Solutions

With effective and timely training, you can turn your lockout tagout program investment into a driver of your mission-critical safety, compliance, and reliability outcomes. We offer in-person, live webinar, and self-paced options to meet your onboarding and scheduling needs.

This standard covers the servicing and maintenance of machines and equipment in which the unexpected energization or start-up of the machines or equipment or release of stored energy could cause injury to employees. This standard establishes minimum performance requirements for the control of such hazardous energy.

Our training solutions include:

- Authorized person training

- Affected employee training

- Contractor protocols

- Guidance for retraining needs

- Custom training program development

The control of hazardous energy is a continuous improvement journey

OSHA 1910.147

Developing and leveraging a comprehensive LOTO program is critical to the safety and success of your people and operations. However, controlling hazardous energy at your facility is a journey rather than a destination. Changes in regulations, equipment, processes, business demands, and workforce will frequently require you to revisit one or more of the critical components of your program.

Digital Lockout Tagout

Power your lockout tagout program management and field implementation with ViewPoint®

Lockout tagout continues to be among the top 10 OSHA-cited standards4 a statistic that underlines the need for improvement in the development and governance of this critical safety program.

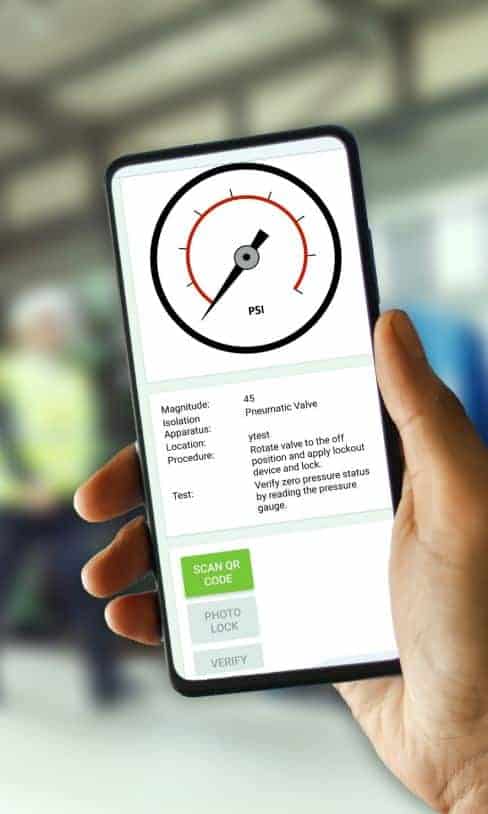

ViewPoint, our proprietary technology solution, helps to digitally transform your LOTO program by enabling you to centralize the creation, editing, and management of procedures and expiration dates so your people can access updated procedures at the point of work via QR code scanning.

4 https://www.nsc.org/newsroom/osha-reveals-top-10-safety-violations-for-fiscal-y

* LOTO procedures cannot be created with this function.

ViewPoint Digital Lockout Tagout

LOTO procedures are commonly paper-based, which can be time-consuming and error-prone. Paper systems can quickly become outdated as your equipment or processes change, increasing the risk of confusion, time waste, and injury. With our proprietary ViewPoint ® technology solution, you can easily create and update LOTO procedures instantly putting them in your people’s hands.

In an instant, everything you need is in your hand.

Enhanced safety

QR code scanning enables your people to confidently follow and confirm each hazardous energy control process step sequentially to reduce errors and increase adherence to your procedures. Additionally, you can require photos to be uploaded to ViewPoint to verify LOTO compliance further.

Improved compliance

ViewPoint Digital Lockout Tagout enables you to create and update procedures when changes or updates occur. You can also access detailed records of LOTO executions with pictures, dates, times, and performance duration. You receive notifications when LOTO procedures are 90 days

Real-time monitoring

Our digital solution provides real-time monitoring and advanced analytics that show LOTO procedures in progress and notify you 90 days before procedures expire.

ViewPoint Digital Lockout Tagout , See it in action.

Beyond Lockout Tagout Procedures

ViewPoint is far more than a lockout tagout tool; it empowers you to make data-informed decisions and show your predictive maintenance program’s impact on energy savings, carbon reduction, downtime avoidance, and more by bringing together.

When you partner with SEAM Group, you gain access to our global team of experts who serve clients across North America, Europe, and Asia.

- Safety-critical information from your LOTO and arc flash programs

- Condition-monitoring insights from:

- Infrared thermography

- Vibration

- Ultrasound

- Motor and oil testing

Don’t leave safety to chance. Let’s work together to achieve lockout tagout success for you and your people.

A Partner for Your Most Demanding Challenges

Leverage our decades of experience with safety, compliance, European Guidelines, NFPA, and OSHA standards. While other providers lead with product and software, we bring a holistic approach to your safety, reliability, and maintenance challenges.